Spirit Distinctive Capabilities

Spirit AeroSystems’ research and development team has identified seven distinctive capabilities — major areas of technological advancement and innovation – that Spirit believes will define the aircraft of tomorrow. These innovative capabilities also help customers understand the value Spirit brings to the market, enabling success in both commercial and defense sectors.

How the Spirit’s Distinctive Capabilities Will Shape the Aircraft of the Future

Spirit AeroSystems has built a reputation as a global manufacturing powerhouse, and not without good reason.

Performance Architecture

Future aircraft will be comprised of fewer total parts. Spirit is working to combine the very best functionality of various aerostructures to reduce the number of parts, making aircraft manufacturing and operation more efficient.

Material Optimization

Research in the area of new and existing materials is key to efficiencies and aircraft performance. Spirit is focused on developing and utilizing the right materials for the right processes.

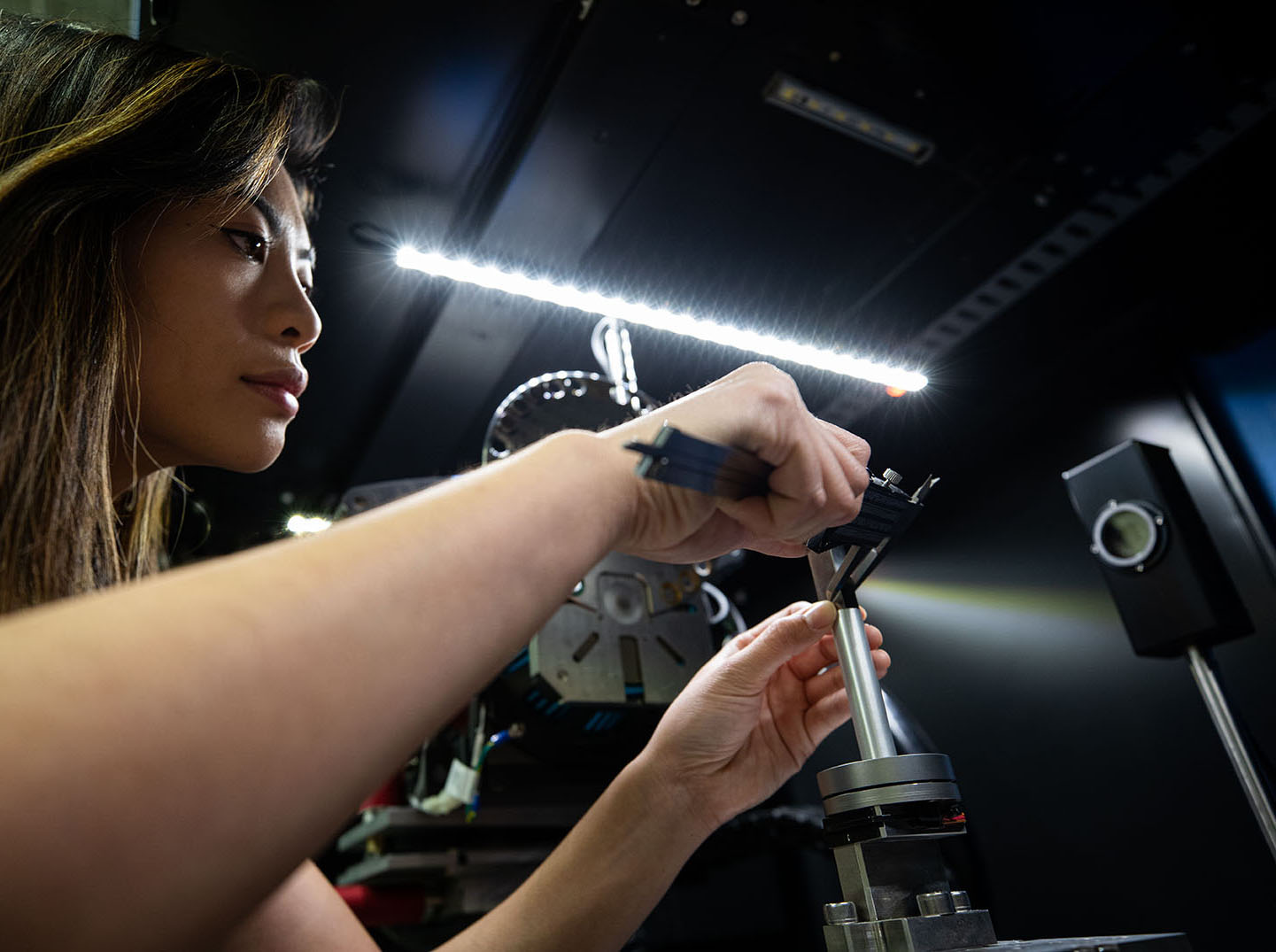

Product Development Software Tools

The need to develop designs, tools and completed aerostructures faster is increasing. Spirit engineers and technicians are developing tools and ideas to help people work faster, better and smarter.

Lean Metallic Structures

At least for the near future, metallic structures will remain a key part of aerospace production. The team at Spirit is bringing new energy to metallic manufacturing, introducing new alloys and other solutions for reducing the number of fasteners and lessening the amount of welding.

Ultra-Competitive Composites

Spirit is working to reduce the costs of composite manufacturing, thereby driving down the total cost for new, lighter, more advanced aircraft.

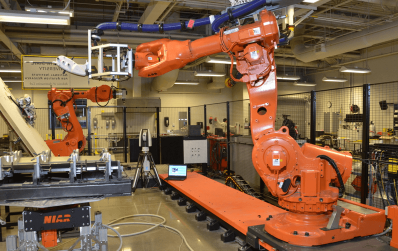

Distinctive Tooling Solutions

Spirit makes some of the world’s most complex and largest tools. These innovations are helping enable higher production rates and will continue to play a part in solving production challenges by matching new, more effective and efficient tools for the task.

Accelerated Learning Curves

Spirit is working to reduce the time needed to ramp up production on new projects. By utilizing digital factory tools and simulated production environments, key personnel can practice operating machinery and master the mechanics of new programs before actual production begins.

Explore More