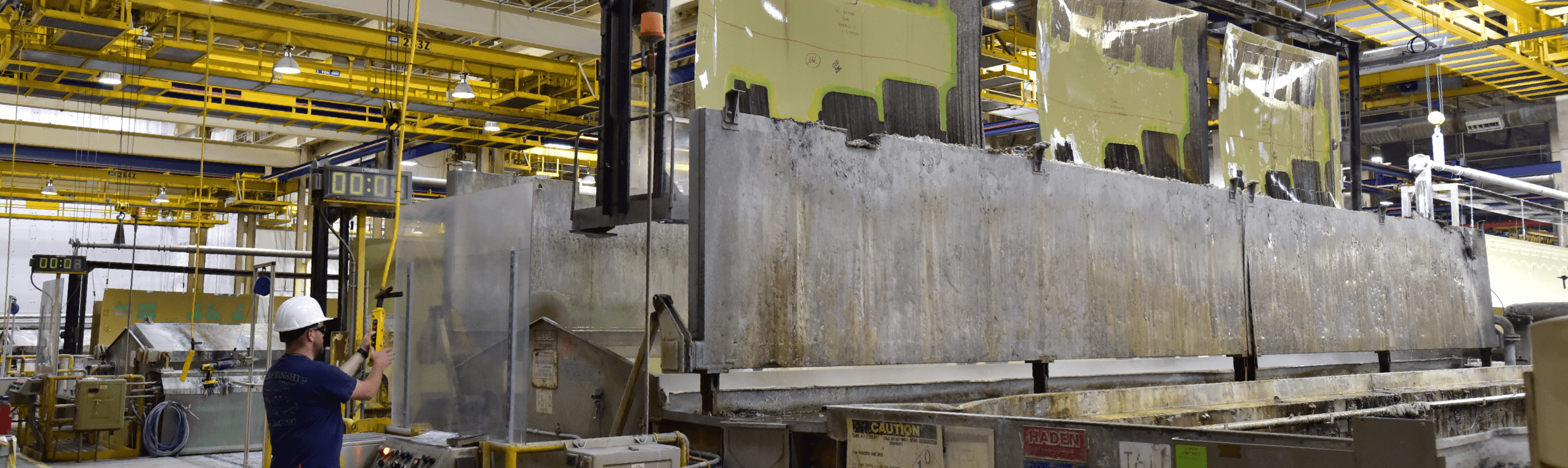

High-Volume Chemical Processing

Spirit AeroSystems’ chemical-processing capabilities accommodate a comprehensive range of hard and soft metals with one of the largest automated lines in the industry. Capable of processing parts up to 48 feet in length, Spirit can manufacture a wide range of finished products — from machined fittings to large fuselage skin panels. Anodizing, chemical milling, cleaning, coating, penetrant processing, plating and surface preparation can be accomplished on a wide variety and size of parts. Also, Spirit’s high-volume, high-velocity processes deliver reliability and an industry-leading turn time.

- High-volume capabilities with a hood launch every 34 minutes

- 4.5 miles of conveyors

- Processing available for parts up to 48 feet

Soft Metal Capabilities

- 16 large tanks (automated)

- 18 small tanks (manual)

- 17 plating tanks (manual)

Hard Metal Capabilities

- Chemical line

- Paint shop

- Penetrant inspection

- Magnetic particle inspection

Additional Processing Capabilities

- Anodizing

- Conversion coating

- Heat processes (part drying) passivation plating

- Penetrant processing

- Stand-alone cleaning and descaling

- Surface preparation for metal bond

© 2024 Spirit AeroSystems, Inc.