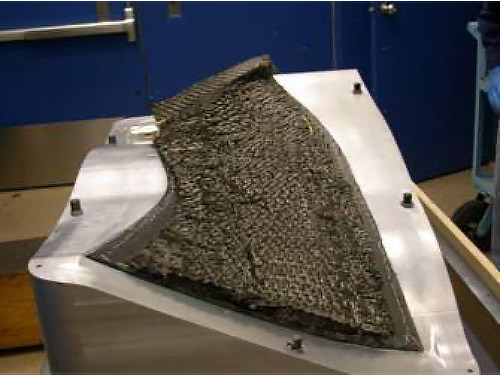

3D Woven Preforms

Modern day Jacquard weaving technology gives the textile designer unique, computer control of every warp fiber in the weaving loom. This enables fabrication of integrally woven features such as flaps, flanges, bi-furcations, tubes, ribs and struts, thickness taper, etc. This also enables tailoring of fiber orientation and directional fiber weightings locally within a preform to correspond to mechanical and/or thermal stresses in the final composite structure. This versatility has been leveraged by Spirit AeroSystems in the fabrication of a diverse array of net shape preforms. Legacy recurring production programs using 3D woven preforms include carbon fiber vanes, blades and airfoils for commercial and military jet engines. Ongoing R&D programs include similar components from ceramic fibers for engine hot section applications.

Product Features:

- Integrally woven bifurcations and flaps

- Integrally woven thickness taper

- Tailored fiber volume and orientation

Product Benefits:

- Delamination resistance

- Damage tolerance

- Reduced part count

- Reduced touch labor

Typical Applications

- Vanes and blades for aircraft engine inlet stages

- Vanes and seal segments for aircraft engine hot section

- Ribs & struts for aircraft structure