New Methods for Rate Readiness

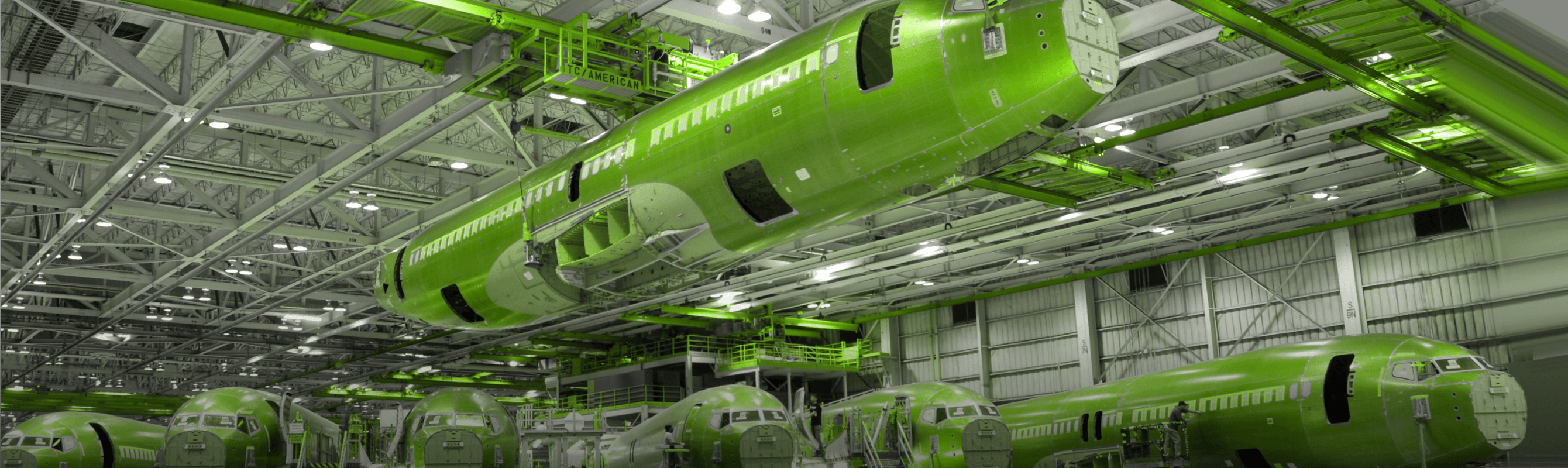

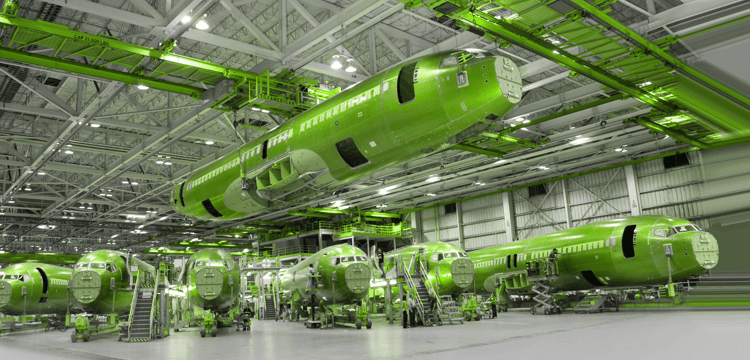

As production rate demands for most commercial programs increase, Spirit AeroSystems is developing innovative solutions for efficiencies at every step of the manufacturing process. Spirit isn’t only applying today’s aerospace manufacturing best practices; the company is often the source of developing and implementing new practices that become the industry standard.

Integrated Product Teams (IPTs)

One key to successful programs and higher production outputs is Spirit’s commitment to Integrated Product Teams, harnessing the power of group problem solving for the benefit of customers. These cross-functional teams include experts from engineering, assembly, operations, quality assurance and testing to create, facilitate and manage projects to meet cost, schedule and performance requirements.

Quality Assurance

Over the years Spirit AeroSystems has developed intellectual property and patented processes to increase production quality, along with consistently applying LEAN manufacturing principles. These processes include quality-tracking systems that measure the rate at which parts are built and quality levels, helping to reduce and eliminate changes and fixes at the end of the line. Real-time scans demonstrate parts perfection or identify what needs to be resolved quickly. Quality feedback is delivered to technicians and engineers, who can then adjust whatever is necessary before the next component is built.

Factory Automation

Spirit achieves the world’s highest manufacturing output with the help of strategic automation. In recent years the company has made significant investments in new technology to increase the level of precision and consistency. Rather than full automation as a goal, Spirit is focused on finding the right level of automation for the appropriate application. With the highest-skilled mechanics in the world, Spirit teams can manufacture certain parts and assemblies faster than automated processes—with higher quality. It is this blend of automation and human expertise that makes Spirit an industry production leader.

Investing in Automation

To meet continuing rate increases, Spirit AeroSystem over the last several years has invested in upgrading and adding automation capabilities to their manufacturing and assembly build processes, optimising both quality and productivity. For instance, automated processes are helping to drill and fasten aluminium panels to sections of aircraft and robotics are being used on thrust reversers and engine nacelles.

Explore More