Demonstrated Engineering Leadership

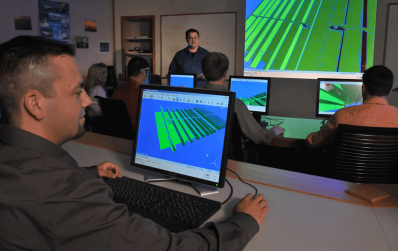

One of the ways Spirit AeroSystems is unique among tier-one suppliers is its breadth and depth of manufacturing work, providing complete program support for all customers. The company’s vast production capabilities are supported by more than 1,500 engineers who continually improve quality and processes for long-standing programs, help design, develop and deliver new products and, in many cases, are given design authority by OEMs.

As a world-class research and development business, Spirit AeroSystems engineers work alongside OEMs on new product development. The ability to design, modify and continually improve components allows Spirit to pass on benefits—such as strength-to-weight advantages and lower costs—to customers. It also helps ensure the seamless integration of components into final assemblies.

Concept to Completion

Spirit engineers support design through all phases of an aerospace program. Rather than only build to print, Spirit engineers design to build in traditional metallic and advanced composite materials for both defense and commercial platforms.

Efficiencies and Savings

Spirit’s engineering expertise translates to real-world cost savings for customers by reducing start-up and initial production expenses. This engineering responsibility and authority also enables Spirit to react quickly, incorporating new technology and advancements into the production and assembly process.

Engineering Capabilities

The 1,500 engineers across Spirit include experts in product development, integrity and certification, stress engineering, precision measurement and program management. Spirit also provides engineering and repair services through Global MRO Solutions.

Technical Services

Spirit is an accredited provider of measurement and test-equipment calibration, testing, repair and engineering technical services. The Spirit Metrology Laboratory is IS017025-compliant, providing NIST traceable calibration services for general purpose test equipment used by the company.