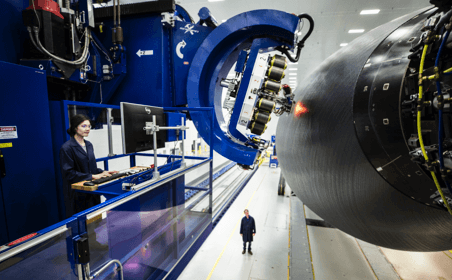

Advanced Composite Fabrication

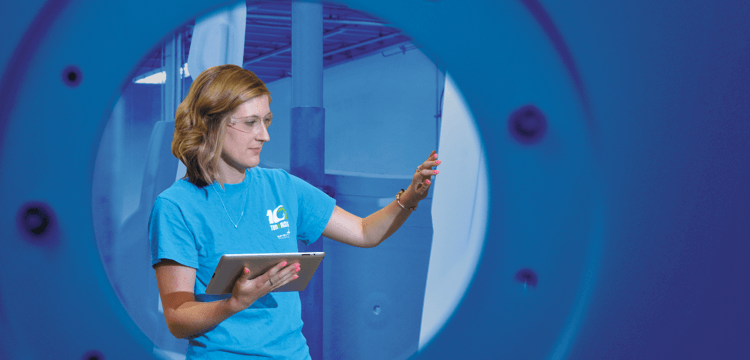

Spirit AeroSystems is a recognized industry leader in advanced composite manufacturing, building large, complex composite parts and structures quickly and at a competitive cost. Spirit offers proven knowledge and experience to adapt composite materials for use in fuselages, nacelles and wing structures.

Current Composite Work

Spirit continues to invest in and expand its advanced composite manufacturing capabilities, creating lighter-weight aerostructure components for both defense and commercial customers.

- Cockpit and cabin for the Sikorsky CH-53K King Stallion

- Center fuselage section and front spar segments for the Airbus A350 XWB

- Next-generation Airbus A320 spoiler

- Thrust reverser inner wall for the Boeing 737 MAX

- Nacelle for the Boeing 777

- Forward (cockpit) section of the Boeing 787 Dreamliner

- Resin Transfer Infusion (RTI) wing for Airbus A220

- Bombardier Global Horizontal Stabiliser

Sikorsky CH-53K King Stallion

Airbus A350 XWB

Boeing 777

Boeing 787 Dreamliner

New Methods for Manufacturing Composites

Aerospace is an intensely competitive global industry, requiring Spirit to stay at the forefront of technology and innovation for products and manufacturing processes. Spirit has the capacity to meet virtually any production demand and deliver the most efficient process for specific customer requirements.

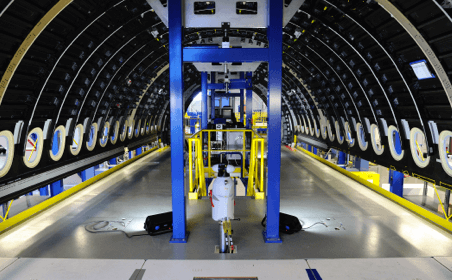

- Spirit AeroSystems is home to more than 30 autoclaves, including a 70’ by 30’ unit that is one of the world’s largest ever used in aerospace manufacturing, with an internal volume of more than 78,000 cubic feet.

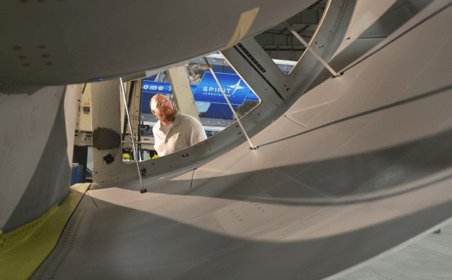

- Spirit is pioneering out-of-autoclave composite manufacturing processes, using resin-infusion technology including vacuum-assisted resin transfer molding. Spirit’s new methods for making out-of-autoclave thermoset and thermoplastic composites led to the development of the next-generation A320 spoiler at our Prestwick, Scotland, site.

- Spirit won the Mac Robert Award for innovation in 2019 for its resin transfer infusion (RTI) Airbus A220 wing. This product is the only certified commercial aircraft wing designed and produced with resin transfer infusion (RTI) rather than pre-impregnated carbon fibre. RTI allows for the manufacture of large, one-piece complex structures, reducing the requirement for many different parts and mechanical fasteners, resulting in significant material saving.

- Spirit’s Inflexion® technology eliminates the need for fasteners. Typically, composite structures are formed using rigid tools that must be removed from inside the product. This limits the complexity and size of the structures. Inflexion technology enables large, complex composite aerostructures to be designed and built for you in one continuous piece, for products that are lighter, more affordable and more efficient.