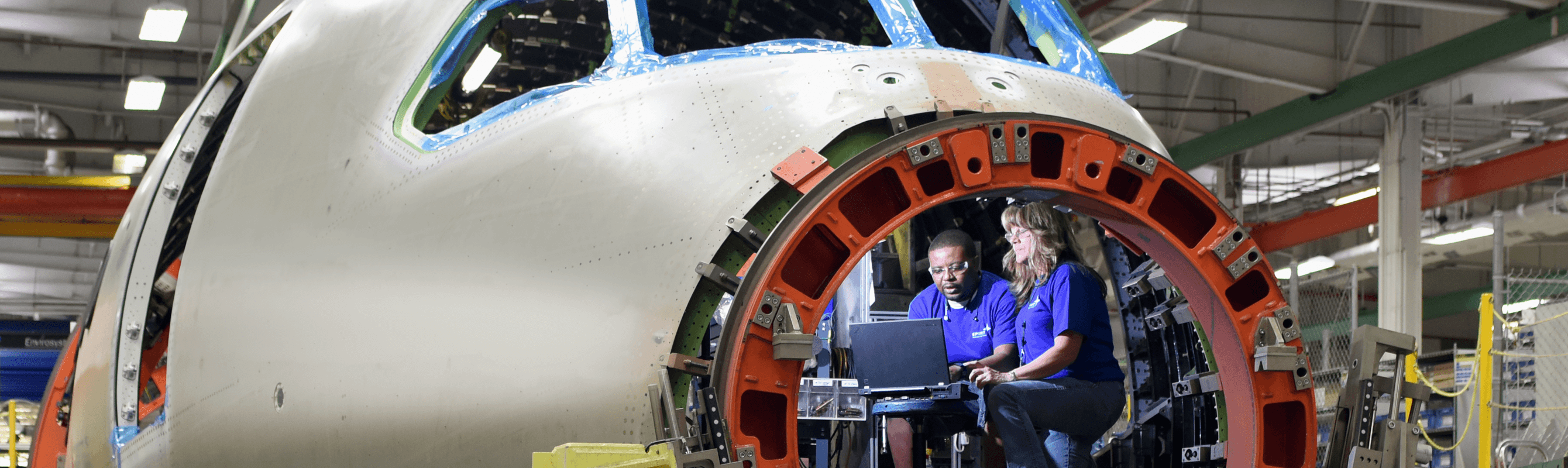

Innovations for Commercial and Defense

As one of the world’s largest tier-one manufacturers and suppliers of aerostructures, Spirit AeroSystems is focused on delivering major portions of the most in-demand aircraft to OEMs and applying engineering innovations to offer new solutions to the warfighter. Many know the company as a commercial production powerhouse, but it is also an emerging center for integrated systems work, a hub for impressive research and development activity and a trusted global source for maintenance and repairs. Discover the Spirit of innovation.

© 2024 Spirit AeroSystems, Inc.