Spirit Solidifies Position as World’s Largest User of AFP Technology

Spirit AeroSystems has accepted delivery of a first-of-its-kind robotic automated fiber placement (AFP) system from Electroimpact (Mukilteo, WA). With more than 15 years of experience with AFP and machines from MTorres, Ingersol and Electroimpact fabricating large composite structures for Boeing, Airbus and defense customers, this new robot will bring Spirit’s overall AFP machine count to 17, solidifying its position as the world’s largest user of AFP technology.

The new machine will be Spirit’s second AFP machine that is 100 percent dedicated to research and development, and the company is seeking to expand its collaborative and contract research utilizing this new capability.

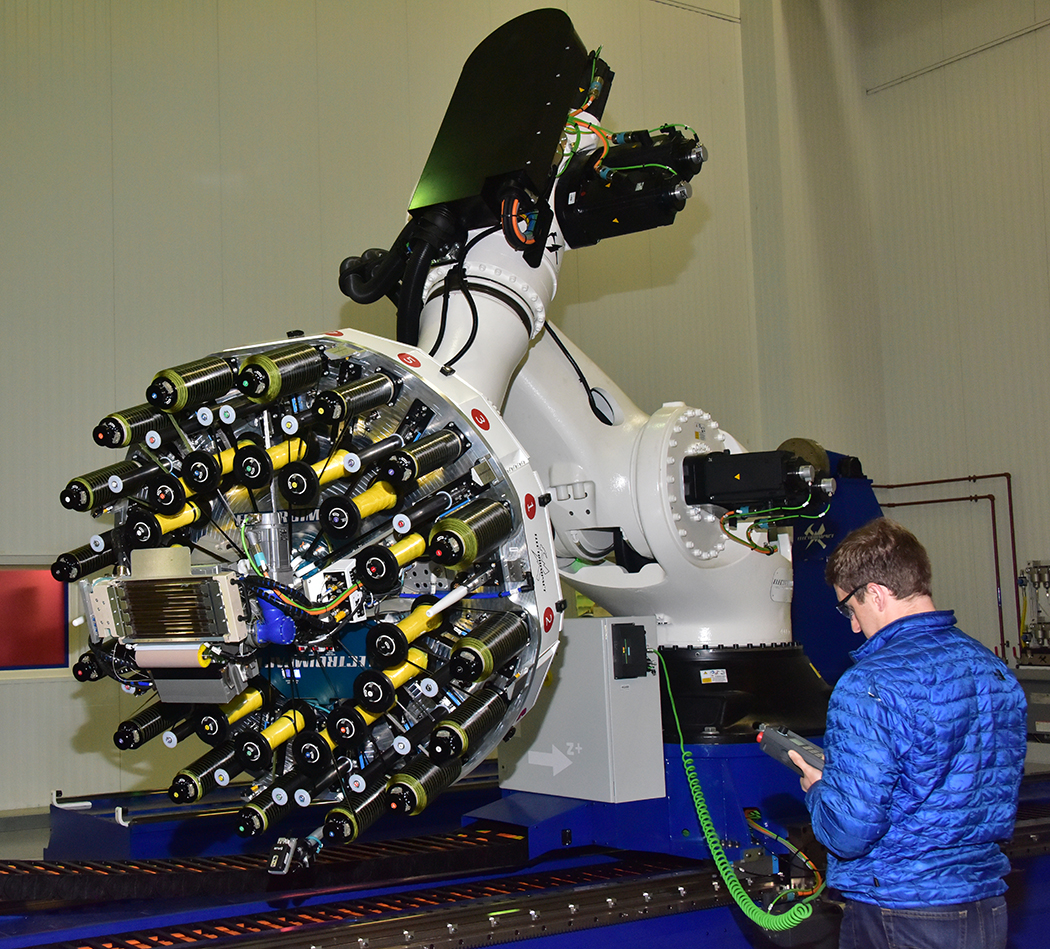

The overall system is comprised of a robot mounted on a rail with an exchangeable attachment, known as the AFP head, which places the carbon fiber onto a part. While a small number of robotic AFP systems have entered the industry, Spirit has accepted the first-of-its-kind, high-speed AFP head. The high-speed AFP head has a series of upgrades, enabling it to place composite material more than twice as fast and nearly three times more reliably than traditional AFP heads.

The new high-speed AFP head also features enhanced accuracy and real-time process monitoring.Todd Rudberg, senior engineer at Electroimpact, describes the high-speed AFP head as “critical to our goals for reaching extreme AFP reliability performance, and more importantly is a giant step towards extreme utilization.”

Spirit’s Research & Technology team is using robotic AFP to expand the limits on of types of parts that can be automatically fabricated, from both a complexity and a price standpoint. Robotic AFP offers additional flexibility, lower cost and a reduced footprint over traditional systems, supporting automation of a more diverse range of complex, smaller composite parts. Spirit technical fellow for composite fabrication Blaise Bergmann had this to say, “The combination of increased speed and reliability of the high-speed AFP is game-changing for AFP and will result in lower capital investment requirements and faster part production on future programs.”

The rail-mounted robotic system has 34 feet of reach and coordinates with a large rotator, capable of holding and rotating tools up to 26 feet long and 13 feet in diameter. The exchangeable heads enable composite material of 1/2”, 1/4” and 1/8” in width as well as an ultrasonic knife for trimming composite parts.

To learn more, contact Spirit’s senior manager for portfolio strategy and collaborative research Scott Bishop.